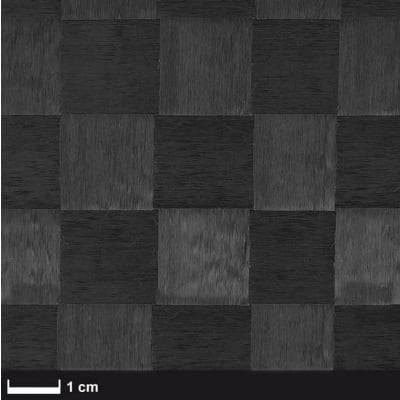

TeXtreme® Carbon fabric 80 g/m² (plain, ± 45 °, HT) 100 cm

USA: width 39.37", weight 2.8 oz/yd²

HT-Fibre type: Tenax® UTS50 12k 800 tex

Fibre orientation ± 45 °:

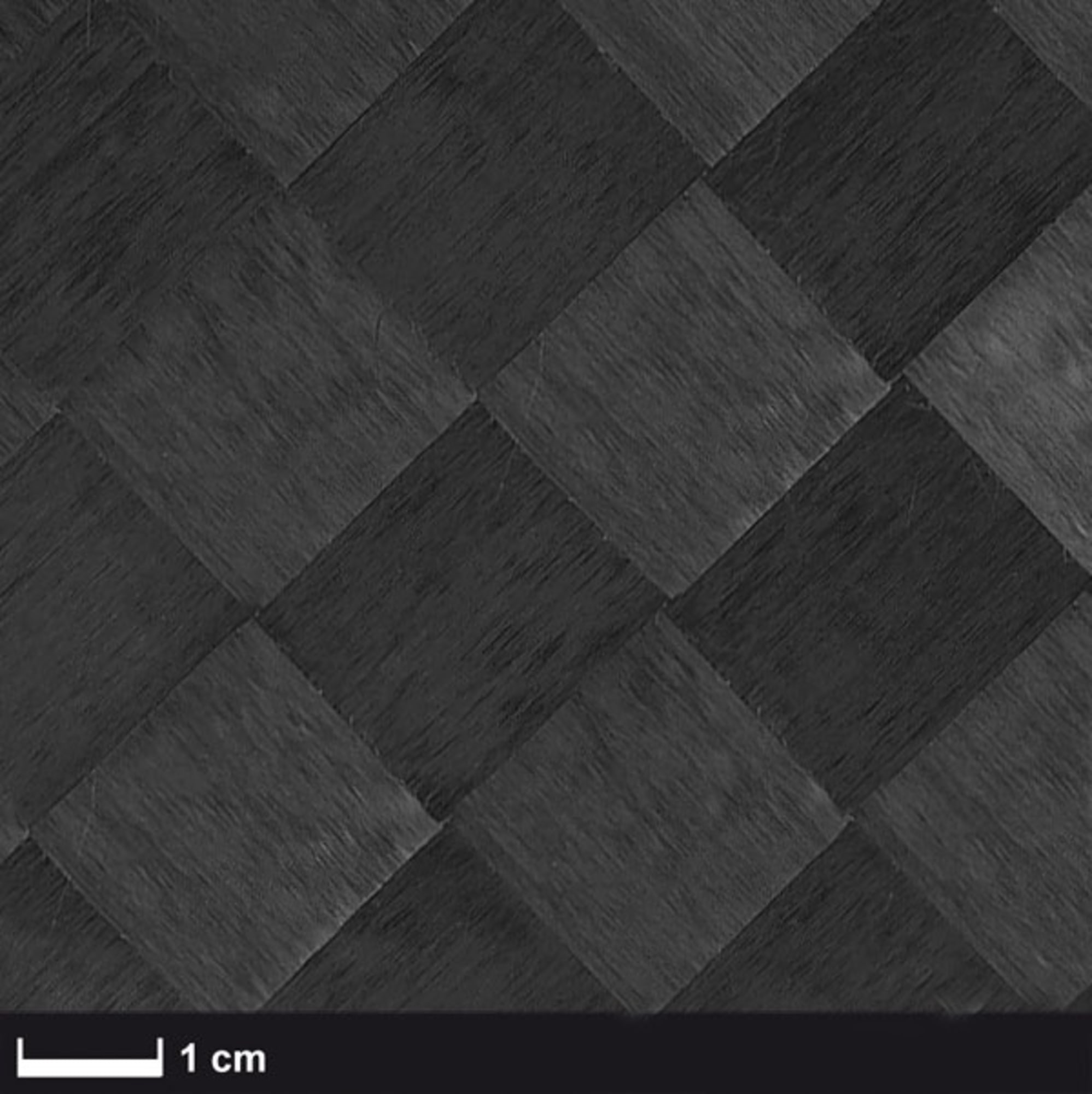

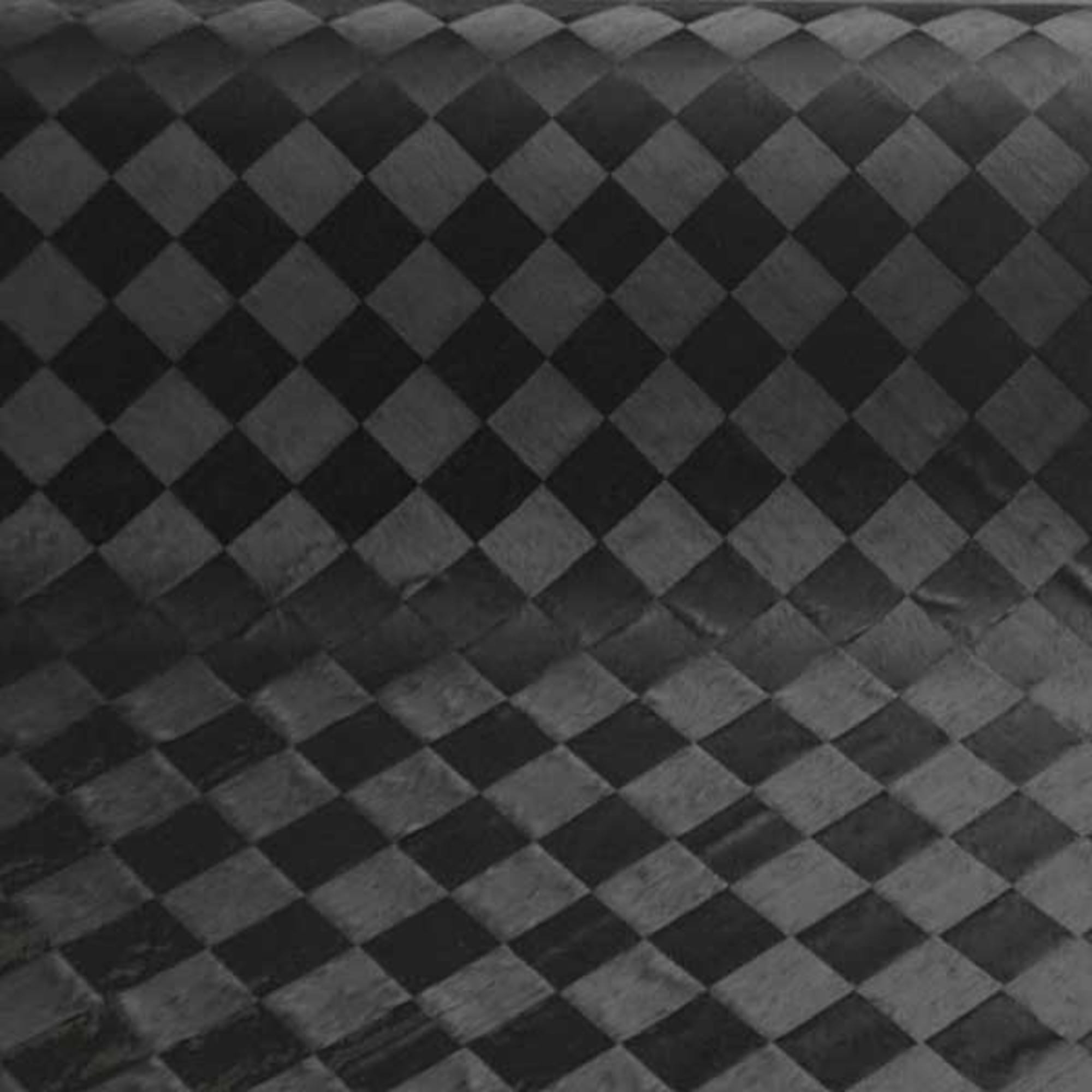

In the TeXtreme® biaxial fabric, the spread tapes are woven at an angle of ± 45 °. The fabric lies very flat and shows only a low ondulation (fiber deflection), which makes better use of the properties of the fibers. Torsion layers can be laminated without waste.

Plain weave

Width: 100 cm

Tape width: 20 mm

Comparison of characteristics of fibres used for TeXtreme® carbon fabric:

|

TeXtreme®

Carbon fabric HT

|

TeXtreme®

Carbon fabric IM

|

TeXtreme®

Carbon fabric HM |

Used fibre

|

Tenax® UTS50 12k

800 tex |

Torayca® M30SC 18K

50C 761 tex |

Tenax® IMS65 24k

830 tex |

Pyrofil™ HR40 12k

600 tex |

| Tensile strength (MPa): |

5100 |

5490 |

6000 |

4410 |

| Tensile modulus(GPa): |

245 |

294 |

290 |

395 |

| Elongation at break (%): |

2.1 |

1.9 |

1.9 |

1.2 |

| Density (g/cm³) |

1.78 |

1.93 |

1.78 |

1.82 |

The specified fabric weight increases by the binder to about 10 g/m³.

Calculated data for hand laminates with 35 volume percent fibres:

Resin consumption: 96 g/m², laminate thickness: 0.13 mm, laminate weight: 176 g/m²

TeXtreme® - Lightweight Carbon Fabric

TeXtreme® Spread Tow Fabric (STF) increases the performance and reduces the weight of your composites as well as enhancing the surface finish making the composites aesthetically appealing. The material is pliable and easy to handle when forming and cutting. TeXtreme® is available in a variety of areal weight and fibre type configurations.

Key benefits of TeXtreme®:

• Reduced weight by 20 % or more

• Increased mechanical performance

• Superior surface finish

• Unique aesthetic look

• Easy to handle and cut due to a stable structure

Notes:

UV resistance: No sensitivity

EP-Binder: 18 °C softening takes place (improved processing at room temperature)

Storage:

The fabric should be stored in a dry and well-ventilated place at room temperature (0 - 30 °C).

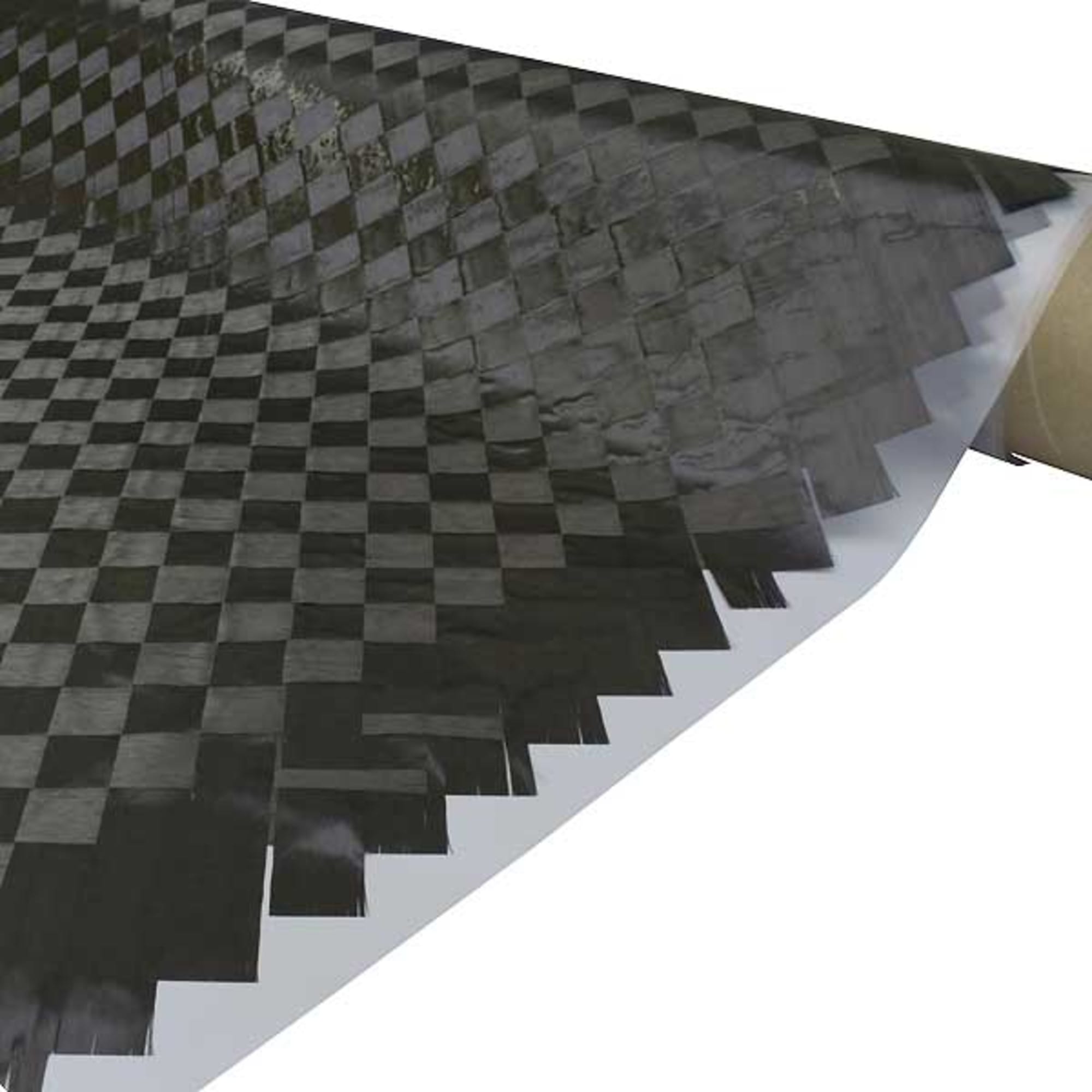

The fabric roll should be stored without load, i.e. the roll must be stored in a stand or in a suitable box so that the paper core can absorb the entire load. R&G guarantees a shelf life of two (2) years from the date of delivery to our customers, provided that the product has been transported, processed, and stored in accordance with the specified requirements.

Delivery:

Textreme® fabrics are generally supplied with a liner film. This prevents the fabric layers from "sticking" together. The high quality of the fabric remains.

Please note:

The manufacturer (OXEON) informed us on request that great progress has been made in quality in recent years, but due to the extremely complicated manufacturing process, unfortunately, no consistently first-class quality can be delivered.

The fibre tapes are not absolutely clean and evenly spread, but this is not a disadvantage for purely technical applications. Unfortunately, this fabric is not or only partially suitable for optical applications. Occasionally weaving errors may occur. These are interrupted fibre tapes which were then joined together by the manufacturer using adhesive tape.

Unfortunately, we cannot select the quality and/or cut out such faulty areas. The manufacturer expressly points out that such irregularities do not constitute errors and are not grounds for complaint.

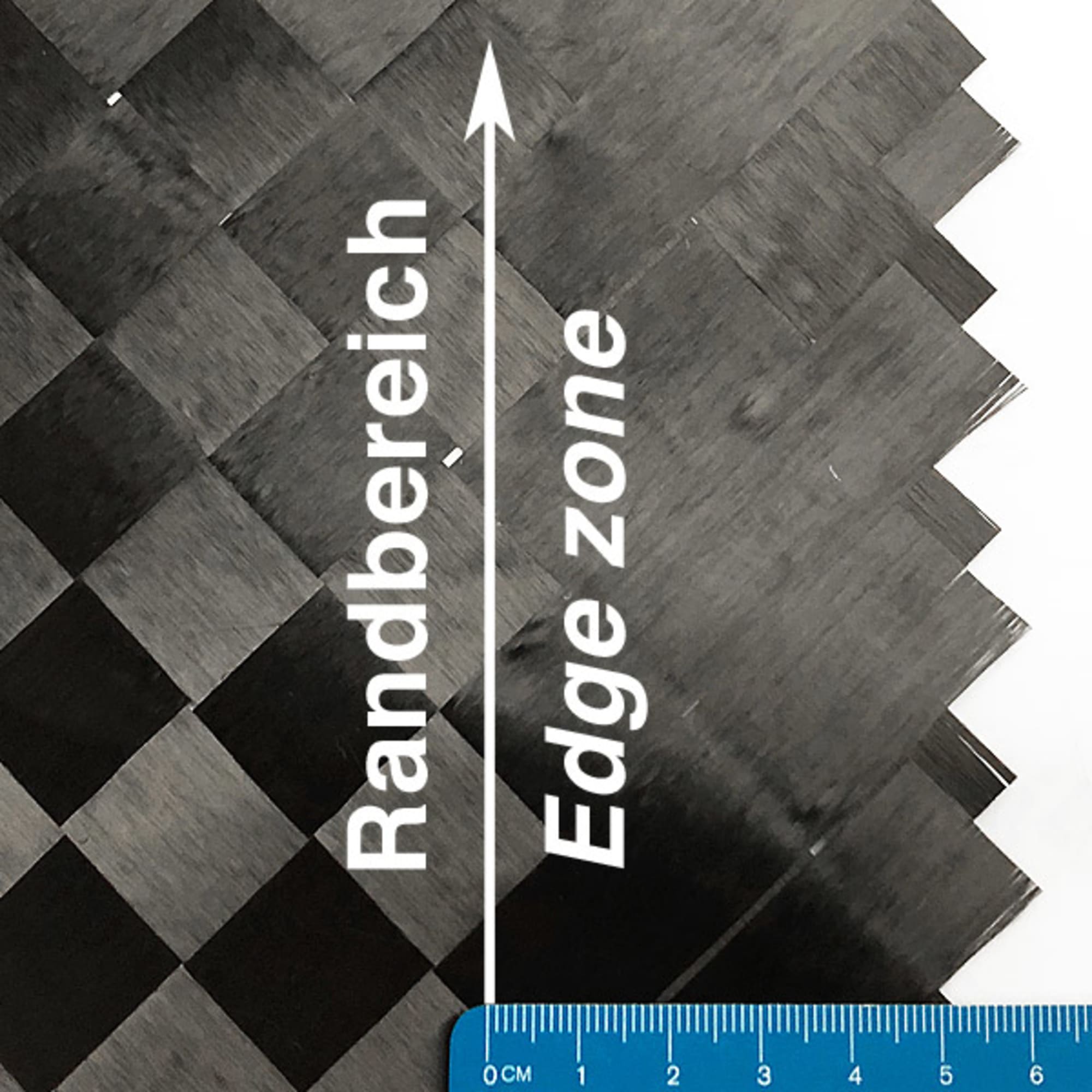

The fabric in ± 45 ° is a novelty and very complicated to manufacture. In the edge area an approx. 5 cm wide strip is irregularly woven. The actual useful width of the fabric lies within a tolerance range of 90-95 cm.

Further information:

TeXtreme on Facebook

Error classification of the manufacturer Oxeon