all Prices price incl. VAT, possibly plus shipping

Article information

Hazards identification - Epoxy Resin MP Advanced

Hazard components for labelling

Tetraglycidyl methylenedianiline1,4-Butandiol-diglycidylether

Signal word: Danger

Pictograms:

Hazard statements

| H315 | Causes skin irritation. |

| H317 | May cause an allergic skin reaction. |

| H318 | Causes serious eye damage. |

| H411 | Toxic to aquatic life with long lasting effects. |

Precautionary statements

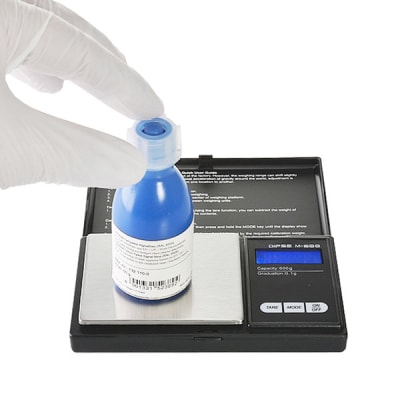

| P280 | Wear protective gloves / protective clothing / eye protection / face protection. |

| P305 P351 P338 | IF IN EYES: Rinse continuously with water for several minutes. Remove contact lenses if present and easy to do. Continue rinsing. |

Hazards identification - Hardener MP Advanced

Hazard components for labelling

DiethylmethylbenzoldiaminCyclohex-1,2-ylendiamin

4,4'-Isopropylidendiphenol; Bisphenol A

4-Toluolsulfonsäure

Signal word: Danger

Pictograms:

Hazard statements

| H302 | Harmful if swallowed. |

| H312 | Harmful in contact with skin. |

| H314 | Causes severe skin burns and eye damage. |

| H317 | May cause an allergic skin reaction. |

| H335 | May cause respiratory irritation. |

| H360 | May damage fertility or the unborn child. |

| H373 | May cause damage to organs through prolonged or repeated exposure. |

| H410 | Very toxic to aquatic life with long lasting effects. |

Precautionary statements

| P201 | Obtain special instructions before use. |

| P260 | Do not breathe dust / fume / gas / mist / vapours / spray. |

| P273 | Avoid release to the environment. |

| P280 | Wear protective gloves / protective clothing / eye protection / face protection. |